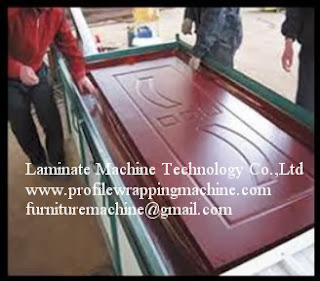

door and cabinet manufacture vacuum membrane press machine

Product Description

1. Stainless heating elements can heat evenly and improve the efficiency.

2. Double layer thermal preservation and full sealing design can save energy.

3. Special steel plate worktable is proof against high temperature and corrosion.

4. Vacuum pump of high quality is efficient, stable and durable.

5. Advanced digital technology can make sure of high level of automation and easy operation.

6. All kinds of products can meet different clients’ needs.

Function:

It can be used to cover PVC on the surface of the craft compound door, furniture, cabinet and sound box and to cover veneer and thermal transfer membrane on single side of the door panel and furniture with the silicon membrane provided by our company.

1. Stainless heating elements can heat evenly and improve the efficiency.

2. Double layer thermal preservation and full sealing design can save energy.

3. Special steel plate worktable is proof against high temperature and corrosion.

4. Vacuum pump of high quality is efficient, stable and durable.

5. Advanced digital technology can make sure of high level of automation and easy operation.

6. All kinds of products can meet different clients’ needs.

Function:

It can be used to cover PVC on the surface of the craft compound door, furniture, cabinet and sound box and to cover veneer and thermal transfer membrane on single side of the door panel and furniture with the silicon membrane provided by our company.

Introduction

Economic Model Double Worktables Manual PVC Vacuum Membrane Press Machine ( TM2480C2) is suitable for a variety of surfaces furniture,wardrobe cabinets,Dingguxian,sliding doors and other stickers cover(can stick coated with PVC film and the transfer materials ,silica gel plate after installation can be pasted on one side of the core board or veneer leather).

TM2480 automatic vacuum laminating machine is mainly appliedto manufacturing and decoration and furniture industry, can be agents of traditional paint process, a variety of decorative panels, furniture and

other decorative surface, suitable for surface mount MDF coating PVC, veneer , ABS plastic and other plastic materials, equipment is simple

other decorative surface, suitable for surface mount MDF coating PVC, veneer , ABS plastic and other plastic materials, equipment is simple

Specifications

Model: TM2480

Total power: 38KW

Working area size : 2550*1250*60mm

Machine overall size: 9200*2200*1750mm

Vacuum pump model: XD-063A

Vacuum pump type: Luozi pump

Heating method :Alumium panel radiating

Heating type:Resistance wire heating

Max processing length :2440mm

Max processing width:1220mm

Max processing thickness:60mm

Working table move speed :10m/min

Max vacuum: -0.1Mpa

Max temperature: 320 degree

Total power: 38KW

Working area size : 2550*1250*60mm

Machine overall size: 9200*2200*1750mm

Vacuum pump model: XD-063A

Vacuum pump type: Luozi pump

Heating method :Alumium panel radiating

Heating type:Resistance wire heating

Max processing length :2440mm

Max processing width:1220mm

Max processing thickness:60mm

Working table move speed :10m/min

Max vacuum: -0.1Mpa

Max temperature: 320 degree